|

May i know composition of your PVC floor? how about the covering percentage?

PVC resin(80%),Calcium polycarbonae(CACO3 10% ),Plasticizer (DOTP),Stabilizer,flamme retardant chemicals with other Additives(10%)

PVC heterogeneous floor can be used in hospital?

Yes, although if thickness is 2mm with 0.4mm wear layer, abrasion resistance can reach "T "group, We don't suggest using in hospitals, because its chemicals resistance is a little bit lower than homogeneous pattern. In addition, if top wear layer and printing layer are damaged based on its laminated structure, white PVC must appear clearly, so this damanged area must be replaced immediately otherwise the hole will become bigger and bigger.

Can you tell me your homogeneous floor rolls advantages?

1. Anti-bacteria 2. Chemicals resistance 3. Anti-slip, water proofing 4. Fire proofing passing EN13501 5. Anti-static resistance 6. Antislip reaching to R9 and R10 7. Scratch resistance. 8. Easy cleaning and maintenance. 9. Excellent bouncing performance from sponge structure.

What is main differnece between homogeneous and heterogeneous rolls ?

1. Structure : homogeneous is single layer , heterogeneous is composed of 6 layers such as UV layer-wear layer-printed layer- PVC layer-fiber glass layer- Back layer .

2. Design: If need customize special design , homogeneous doesn't need invest on embossing cylinder ,but heterogeneous must need due to one design matching one embossing cylinder. However, customized homogeneous floor needs reach 3000 sqm MOQ basically, and heterogeneous customized design needs invest the embossing cylinder and reach 50000sqm per year.

3. Maintenance: just need clean and wax once damaged by man- made breaking; however, heterogeneous must be replaced by new piece specially.

4. Chemicals resistance: Homogeneous is best especially Relle owns unique coating in the world. However, this is weak for heterogeneous. 5. Abrasion resistance : Thickness over than 2mm with 0.4mm wear layer, all items can reach T group. But Homogeneous can be divided into M, P and T depends on the floor weight ,which is lighter , abrasion resistane is higher , means calcium polycarbonate filler is less. 6. Color fastness: both of them can reach 6 class, but heterogeneous will be better if fixed in corridor without curtains due to there is wear layer and UV layer protection. However, we suggest fixing curtains in corridor or don't use vinyl floor if without ,due to this is indoor floor material not outdoor.

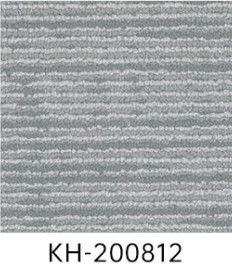

Which item is most popular for your homogeneous rolls sales in the world?

It is homogeneous non-directional series, due to all performance are best especially for grains design which cannot be found easily once breaking by man-made.

Documents

|